Expert Guide to Electroplated Sandpaper

Introduction

Welcome to our expert guide on electroplated sandpaper. In this article, we will delve into the world of electroplated sandpaper, exploring how it works, its advantages, applications, and tips for using it effectively.

Electroplated sandpaper is a type of abrasive paper that has diamond particles electroplated onto its surface. This unique manufacturing process ensures that the diamond particles are permanently bonded to the paper, providing exceptional durability and efficiency in sanding various hard and abrasive materials.

Unlike traditional spot pads or resin polishing pads, electroplated sandpaper offers a more aggressive and long-lasting performance. With 100% diamond exposure, it delivers an impressive removal rate, making it a preferred choice for professionals and enthusiasts alike.

One of the key advantages of electroplated sandpaper is its versatility. It can be used for a wide range of applications, including polishing granite, concrete, marble, glass, porcelain, tiles, and even metal surfaces. Whether you are working on art and crafts, woodworking, automotive projects, or metal and plastic applications, electroplated sandpaper is a reliable tool that ensures high efficiency and excellent results.

Choosing the right grit for your project is crucial, as it determines the level of abrasion and the desired finish. We will provide useful insights and recommendations on selecting the appropriate grit for your specific needs.

To help you make the most out of electroplated sandpaper, we will also share valuable tips on how to use it effectively and maintain its performance over time.

Stay tuned as we dive deeper into the world of electroplated sandpaper, uncovering its secrets and empowering you with the knowledge to achieve professional-quality results in your sanding projects.

How Electroplated Sandpaper Works

Electroplated sandpaper is a unique type of abrasive paper that is coated with diamond particles through an electroplating process. This innovative technique ensures that the diamond particles are permanently bonded to the surface of the paper, resulting in a highly efficient and durable sanding tool.

The electroplated diamond particles on the sandpaper provide exceptional abrasion resistance, allowing for effective sanding of hard and abrasive materials such as glass, ceramics, and stone. The diamonds act as cutting edges, removing material quickly and efficiently.

One of the key advantages of electroplated sandpaper is its ability to maintain a sharp cutting edge throughout its lifespan. The diamond particles are evenly distributed across the surface of the sandpaper, ensuring consistent performance and preventing premature wear.

The design of electroplated sandpaper also allows for flexibility, making it suitable for use on curved or irregular surfaces. The soft backing paper ensures a good fit to your hand, providing comfort and control during sanding.

Electroplated sandpaper can be used both wet and dry, depending on the specific application. When used wet, it helps to reduce heat and prevent clogging, resulting in a smoother and more efficient sanding process.

Overall, electroplated sandpaper offers a high-quality finish and long-lasting performance. Its versatility and effectiveness make it an essential tool for various industries, including art and craft, woodworking, automotive, metalworking, and plastic applications.

In the next section, we will explore the advantages of using electroplated sandpaper and how it can benefit your projects.

Advantages of Electroplated Sandpaper

When it comes to sanding and polishing hard surfaces like glass, ceramics, and stone, electroplated sandpaper offers several advantages over traditional options. Here are some key benefits of using electroplated sandpaper:

Aggressive and Efficient: The unique arrangement of diamonds in electroplated sandpaper makes it more aggressive and long-lasting compared to traditional spot pads. This means you can achieve a higher level of abrasion resistance and efficiency in your sanding and polishing tasks.

Versatile Applications: Electroplated sandpaper is suitable for various applications, including art and crafts, woodworking, automotive, metal, and plastic polishing. Its versatility allows you to use it on different surfaces and materials, making it a valuable tool in your toolbox.

Easy Identification: The grits of the sandpaper are printed on the back, making it easy to identify the right grit for your specific needs. This saves you time and ensures you can quickly select the appropriate sandpaper for your project.

Durable and Long-lasting: Electroplated sandpaper is designed to be durable and long-lasting. Its sharp diamond particles are permanently bonded to the surface, ensuring a high-quality finish and extended usability.

Flexible and Conforming: The flexibility of electroplated sandpaper allows it to conform to curved or irregular surfaces, making it ideal for tackling complex shapes and contours.

Wet and Dry Usage: Electroplated sandpaper can be used both wet and dry, providing flexibility in different working conditions. Whether you prefer wet sanding or dry sanding, this type of sandpaper can adapt to your preferences.

In conclusion, electroplated sandpaper offers numerous advantages, including its aggressive and efficient performance, versatility in applications, easy identification of grits, durability, flexibility, and suitability for both wet and dry usage. These benefits make it an excellent choice for professionals and DIY enthusiasts looking to achieve high-quality results in their sanding and polishing projects.

Applications of Electroplated Sandpaper

When it comes to applications, electroplated sandpaper offers a wide range of uses due to its unique properties and versatility. Here are some common applications where electroplated sandpaper excels:

Metalworking: Electroplated sandpaper is highly effective for metalworking applications. It can be used for shaping, smoothing, and polishing various metals, including steel, aluminum, and brass. Whether you're working on automotive parts, jewelry, or metal sculptures, electroplated sandpaper provides excellent results.

Woodworking: Electroplated sandpaper is also ideal for woodworking projects. It can be used for sanding and refining wood surfaces, removing imperfections, and preparing surfaces for finishing. From furniture restoration to cabinetry, electroplated sandpaper ensures a smooth and flawless finish.

Glass and Ceramic: Electroplated sandpaper is a go-to choice for working with glass and ceramic materials. It effectively removes scratches, smoothens edges, and polishes surfaces, making it invaluable for glass artists, tile installers, and ceramic craftsmen.

Stone and Concrete: Whether you're working with natural stone or concrete, electroplated sandpaper is essential for achieving a professional finish. It can be used for leveling uneven surfaces, grinding down rough patches, and polishing stone countertops, floors, and sculptures.

DIY and Crafts: Electroplated sandpaper is a versatile tool for various DIY projects and crafts. It can be used for refinishing furniture, sanding wooden crafts, smoothing 3D-printed objects, and even shaping materials like resin and plastic.

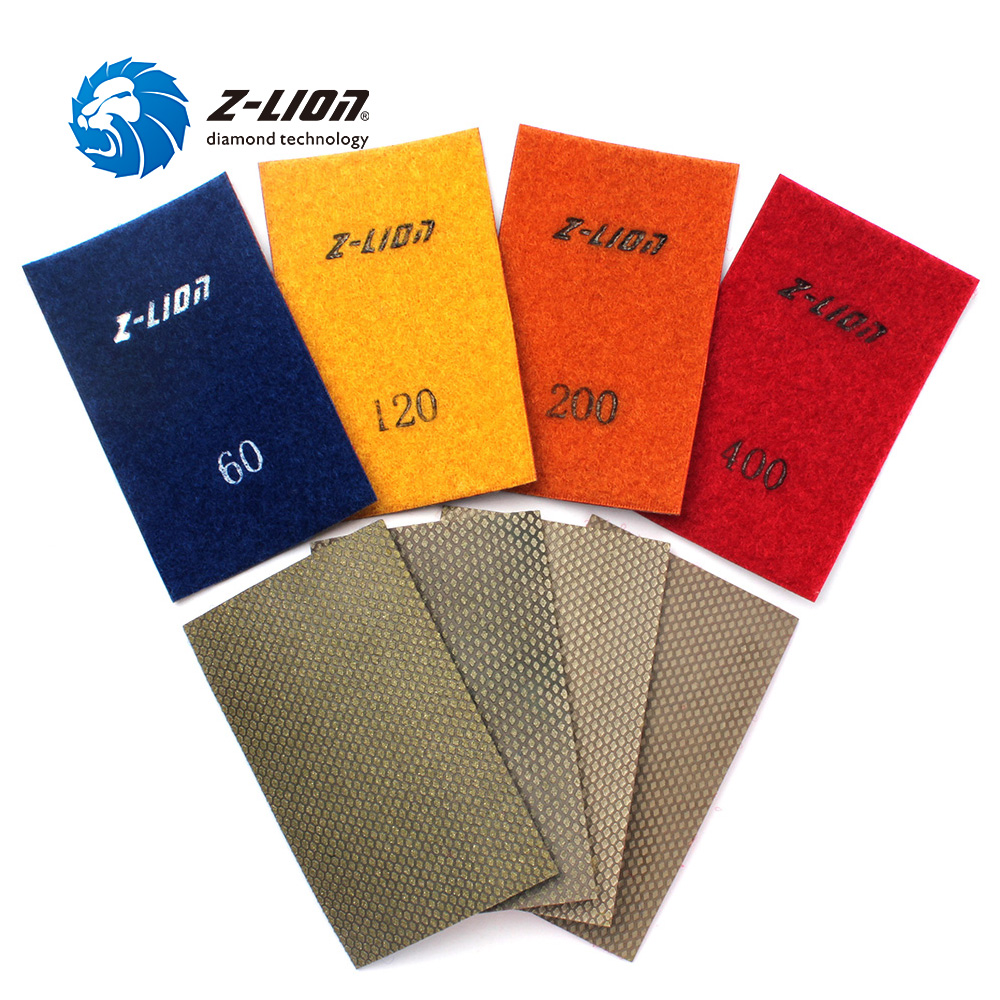

Remember, the grit size of the electroplated sandpaper will determine the level of abrasiveness. Coarser grits, such as 60 or 120, are suitable for heavy material removal, while finer grits like 400 are ideal for achieving a smooth and polished finish.

No matter the application, electroplated sandpaper offers exceptional performance, durability, and efficiency. Its ability to conform to curved or irregular surfaces makes it a valuable asset in any project. So, whether you're a professional craftsman or a DIY enthusiast, electroplated sandpaper is a must-have tool in your arsenal.

Choosing the Right Grit for Your Project

When it comes to choosing the right grit for your project, there are a few factors to consider. The grit of electroplated sandpaper determines the level of abrasiveness and the type of finish it will achieve.

Firstly, you need to assess the material you are working with. Different materials require different grits for optimal results. For example, if you are working with glass, ceramics, or stones, a finer grit such as 400 would be suitable for achieving a smooth and polished finish. On the other hand, if you are working with metal or plastic, a coarser grit like 60 or 120 would be more effective in removing imperfections and shaping the material.

Secondly, consider the desired outcome of your project. If you need to remove a significant amount of material or reshape a surface, a coarser grit will be more efficient. However, if you are looking to refine and smooth out a surface, a finer grit will be necessary.

It's also important to keep in mind that electroplated sandpaper can be used wet or dry. Wet sanding helps to prevent clogging and provides a smoother finish. If you choose to use it wet, make sure to select a grit that is suitable for wet applications.

Lastly, consider the level of aggressiveness you require. Higher grits, such as 400, are less aggressive and suitable for finer polishing, while lower grits, such as 60 or 120, are more aggressive and ideal for rough shaping and removing material quickly.

By carefully considering the material, desired outcome, and level of aggressiveness, you can choose the right grit of electroplated sandpaper that will effectively meet your project's needs. Remember to always follow the manufacturer's recommendations and guidelines for optimal results.

Tips for Using Electroplated Sandpaper

When it comes to using electroplated sandpaper, there are a few tips and tricks that can help you achieve the best results. Whether you are a professional or a DIY enthusiast, these tips will ensure that you make the most of your sanding projects.

Choose the Right Grit: The grit of the sandpaper determines its coarseness and the level of abrasion it provides. For rougher surfaces, such as glass, ceramics, or stone, opt for lower grits like 60 or 120. For finer finishes, higher grits like 200 or 400 are more suitable. Consider the material you are working on and select the appropriate grit for optimal results.

Use Wet or Dry: Electroplated sandpaper can be used both wet and dry, depending on the application. Wet sanding is ideal for preventing dust and keeping the surface cool, while dry sanding is more convenient for quick touch-ups. Consider the nature of your project and choose the method that suits it best.

Apply Even Pressure: When using electroplated sandpaper, it's important to apply even pressure to ensure consistent results. Avoid pressing too hard, as it can lead to uneven sanding or damage the surface. Instead, use a gentle and controlled motion to achieve a smooth and uniform finish.

Keep the Sandpaper Clean: As you sand, the sandpaper can become clogged with debris and lose its effectiveness. To prevent this, regularly clean the sandpaper by tapping it against a hard surface or using a cleaning brush. This will help maintain its cutting ability and prolong its lifespan.

Work in Stages: For larger projects, it's often more efficient to work in stages. Start with a coarser grit to remove any imperfections or rough surfaces, and gradually move to finer grits for a smoother finish. This step-by-step approach ensures better control and allows you to achieve the desired result with precision.

Remember, practice makes perfect when it comes to using electroplated sandpaper. Don't be afraid to experiment and adjust your technique as needed. With these tips in mind, you'll be able to tackle any sanding project with confidence and achieve professional-quality results.

Maintenance and Care of Electroplated Sandpaper

Taking proper care of your electroplated sandpaper is essential to ensure its longevity and optimal performance. Here are some maintenance and care tips to keep in mind:

Cleaning: After each use, it is important to clean your electroplated sandpaper to remove any debris or particles that may have accumulated. Use a soft brush or compressed air to gently remove the residue. Avoid using harsh chemicals or abrasive cleaners, as they can damage the electroplated surface.

Storage: Proper storage is key to preserving the quality of your electroplated sandpaper. Store it in a dry and clean environment, away from moisture and direct sunlight. Consider using a storage box or pouch to protect it from dust and other contaminants.

Avoid Excessive Pressure: While using electroplated sandpaper, avoid applying excessive pressure on the surface. Let the diamond particles do the work by applying light to moderate pressure. Excessive pressure can cause premature wear and reduce the effectiveness of the sandpaper.

Use with Lubrication: When using electroplated sandpaper, it is recommended to use it with a lubricant or coolant. This helps to reduce friction, prevent overheating, and prolong the life of the sandpaper. Water or a specialized lubricant can be used depending on the application.

Inspect Regularly: Regularly inspect your electroplated sandpaper for any signs of wear or damage. Look for any loss of diamond particles or uneven wear patterns. If you notice any significant damage or deterioration, it may be time to replace the sandpaper.

By following these maintenance and care guidelines, you can ensure that your electroplated sandpaper remains in optimal condition, providing you with consistent performance and longevity. Remember to always prioritize safety and use proper protective equipment when working with sandpaper.

-All diamond tools can be ordered and fabricated!

-Henry Wang | Quote Manager

-WhatsApp:+86-18030177538

-Email: ceo@zdiamondtools.com

-Web www.zdiamondtools.com