Expert Tips for Using 1600mm Granite Cutting Discs

Introduction

Welcome to our expert tips for using 1600mm granite cutting discs. As professionals in the stone cutting industry, we understand the importance of using the right tools for the job. When it comes to cutting large granite blocks, 1600mm granite cutting discs are the go-to choice for many professionals.

In this article, we will provide you with valuable insights and advice on how to make the most of your 1600mm granite cutting discs. From the benefits of using these discs to factors to consider when choosing them, we have you covered. We will also share proper techniques for using these discs, maintenance and care tips, as well as common issues and troubleshooting advice.

Our goal is to help you become more knowledgeable and confident in using 1600mm granite cutting discs. Whether you are a seasoned professional or just starting out in the industry, our expert tips will provide you with the information you need to achieve optimal results.

So, let's dive in and discover the world of 1600mm granite cutting discs. Get ready to enhance your cutting efficiency, improve your productivity, and achieve outstanding results in your granite cutting projects.

Benefits of Using 1600mm Granite Cutting Discs

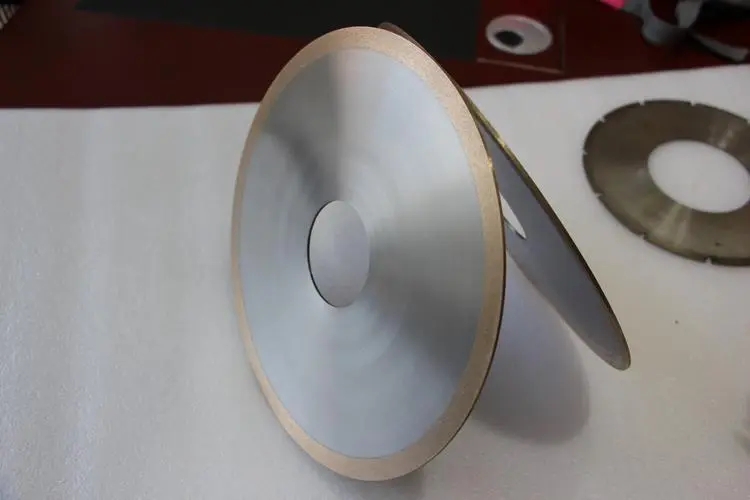

When it comes to cutting large granite blocks, using the right tools is essential for achieving precise and efficient results. One such tool that stands out in the industry is the 1600mm granite cutting disc. Designed specifically for cutting maximum 65cm granite strips or tiles, these discs offer a range of benefits that make them a popular choice among professionals.

Superior Cutting Performance: The 1600mm granite cutting discs are made with high-quality diamond segments, which provide exceptional cutting performance. The synthetic diamond powder and metal powder used in the segments, along with sintering technology, ensure that the discs can effortlessly cut through granite blocks to create slabs for various applications.

Versatile Applications: These cutting discs are suitable for use on bridge block cutters, gantry or single arm block cutters, and can handle both hard and soft to medium-hard granites. With the option of choosing between different bond types and segment structures, users have the flexibility to select the most suitable disc for their specific cutting needs.

Efficient and Time-saving: The 1600mm granite cutting discs are designed to provide fast and efficient cutting, allowing users to complete their projects in a timely manner. The automatic high frequency segment welding or brazing technology used in the manufacturing process ensures precise control over heating time, resulting in discs that are durable and resistant to bending or overheating.

Cost-effective: By using high-quality 1600mm granite cutting discs, professionals can achieve excellent cutting performance and durability, ultimately saving on replacement costs. These discs are designed to withstand the demands of heavy-duty cutting, reducing the need for frequent disc changes and increasing productivity.

In conclusion, the benefits of using 1600mm granite cutting discs are numerous. From superior cutting performance to versatility and cost-effectiveness, these discs are an essential tool for professionals in the stone cutting industry. Whether it's for flooring or paving purposes, investing in high-quality 1600mm granite cutting discs ensures precise and efficient cutting, leading to successful projects and satisfied customers.

Factors to Consider When Choosing 1600mm Granite Cutting Discs

When it comes to choosing the right 1600mm granite cutting discs, there are several factors to consider. These factors will ensure that you select the most suitable disc for your specific cutting needs. Here are some key considerations to keep in mind:

Diamond Segment Bond: The bond of the diamond segment plays a crucial role in the performance of the cutting disc. For hard granites, a soft bond diamond segment is recommended, while for soft to medium hard granites, a harder bond is more suitable. It's important to choose a disc with the appropriate bond to ensure efficient and effective cutting.

Segment Structure: The structure of the diamond segments is another important factor to consider. There are options available such as sandwich or multi-layer structures, as well as square segments and M shape segments. Each structure has its own advantages and suitability for different cutting applications. Consider the specific requirements of your project and choose the segment structure that best meets your needs.

Quality and Durability: It's essential to select a high-quality cutting disc that is durable and long-lasting. Look for discs made with synthetic diamond powder and metal powder, using sintering technology. This ensures a solid segment that can withstand the demands of granite block cutting. Additionally, choose a disc that has undergone thorough inspection and testing to ensure it meets the required quality standards.

Compatibility: Ensure that the 1600mm granite cutting disc you choose is compatible with your cutting equipment. Check the specifications of your saw blade and make sure the disc fits properly. Using an incompatible disc can lead to poor performance and potential safety hazards.

By considering these factors when choosing your 1600mm granite cutting disc, you can ensure optimal performance, efficiency, and durability. Remember to always prioritize quality and suitability for your specific cutting needs.

Proper Techniques for Using 1600mm Granite Cutting Discs

When it comes to using 1600mm granite cutting discs, proper techniques are essential to ensure optimal performance and safety. Here are some expert tips to help you make the most out of your cutting discs:

Choose the right disc: Before starting any cutting project, make sure you have selected the appropriate disc for the job. Consider factors such as the type of granite, the thickness of the material, and the desired cut. For hard granites, opt for discs with a softer bond, while for softer to medium-hard granites, choose discs with a harder bond.

Ensure proper installation: Properly install the 1600mm cutting disc onto your saw blade, following the manufacturer's instructions. Check for any damage or wear on the disc before use, as this can affect its performance and safety.

Use the correct cutting technique: When cutting granite, it is important to use the correct cutting technique to achieve clean and precise cuts. Start by positioning the disc at a slight angle to the material, allowing the diamond segments to gradually penetrate the granite. Apply steady and even pressure throughout the cutting process to avoid chipping or overheating.

Cooling and lubrication: To prevent overheating and extend the life of your cutting disc, ensure proper cooling and lubrication. Use water or a suitable coolant to keep the disc and the granite cool during cutting. This will also help to reduce dust and debris.

Safety precautions: Always prioritize safety when using 1600mm granite cutting discs. Wear appropriate personal protective equipment, such as safety glasses, gloves, and hearing protection. Follow all safety guidelines provided by the manufacturer and ensure a stable and secure work environment.

By following these proper techniques, you can maximize the performance and longevity of your 1600mm granite cutting discs, achieving precise and efficient cuts in your granite projects. Remember to always prioritize safety and consult the manufacturer's instructions for specific guidance.

Maintenance and Care for 1600mm Granite Cutting Discs

Taking proper care of your 1600mm granite cutting discs is essential to ensure their longevity and optimal performance. Here are some expert tips to help you maintain and care for your cutting discs:

Regular Cleaning: After each use, make sure to clean the cutting disc thoroughly. Remove any debris, dust, or residue that may have accumulated during the cutting process. This will prevent the buildup of material on the disc, which can affect its cutting efficiency.

Proper Storage: Store your cutting discs in a dry and clean area to protect them from moisture and dust. Avoid stacking them on top of each other, as this can cause damage to the discs. Use protective covers or cases to keep them safe from any potential impact or accidental damage.

Inspect for Damage: Before each use, carefully inspect your cutting discs for any signs of damage or wear. Look for cracks, chips, or uneven segments, as these can affect the disc's performance and pose a safety risk. If you notice any damage, replace the disc immediately.

Use Correct Techniques: Follow the manufacturer's instructions and recommendations for proper usage of the cutting discs. Ensure that you are using the appropriate cutting speed, pressure, and coolant, if required. Using the discs correctly will not only enhance their performance but also prevent unnecessary wear and tear.

Sharpening and Maintenance: When your cutting discs start to lose their sharpness, it's important to have them professionally sharpened or replaced. Dull discs can lead to inefficient cutting and can put excessive strain on your equipment. Regular maintenance will ensure that your cutting discs are always in optimal condition.

By following these maintenance and care tips, you can extend the lifespan of your 1600mm granite cutting discs and ensure consistent and precise cutting performance. Remember, proper maintenance is key to achieving the best results and maximizing the value of your cutting discs.

Common Issues and Troubleshooting for 1600mm Granite Cutting Discs

When using 1600mm granite cutting discs, there are a few common issues that may arise. However, with the right troubleshooting techniques, these issues can be easily resolved. Here are some tips to help you overcome these challenges:

Overheating: One common issue with granite cutting discs is overheating. This can occur when the disc is used for an extended period of time or when excessive pressure is applied. To prevent overheating, make sure to use the correct cutting speed and apply consistent pressure. If the disc starts to overheat, stop cutting and allow it to cool down before continuing.

Segment Loss: Another issue that may occur is segment loss, where the diamond segments detach from the disc. This can happen due to improper bonding or excessive wear. To prevent segment loss, choose a high-quality disc with strong bonding and regularly inspect the segments for any signs of wear. If segment loss does occur, replace the disc immediately to avoid any accidents.

Chipping or Cracking: Chipping or cracking of the granite can also be a problem when using cutting discs. This can happen if the disc is not properly aligned or if too much pressure is applied. To avoid chipping or cracking, ensure that the disc is securely mounted and aligned correctly. Use steady and controlled cutting motions, applying just enough pressure to cut through the granite without causing damage.

Uneven Cutting: Uneven cutting can occur if the disc is not properly balanced or if the segments are worn unevenly. To ensure even cutting, regularly check the disc for balance and replace any worn segments. Additionally, make sure to use a consistent cutting speed and apply even pressure throughout the cutting process.

By following these troubleshooting tips, you can overcome common issues and achieve optimal results when using 1600mm granite cutting discs. Remember to always prioritize safety and use the appropriate safety equipment when operating cutting tools.

-All diamond tools can be ordered and fabricated!

-Henry Wang | Quote Manager

-WhatsApp:+86-18030177538

-Email: ceo@zdiamondtools.com

-Web www.zdiamondtools.com