The Art of Diamond Cutting

The Importance of a Skilled Diamond Cutter

A skilled diamond cutter is an essential component in the creation of a truly remarkable diamond. The art of diamond cutting requires years of training and experience, as well as a deep understanding of the unique properties of diamonds.

When it comes to diamond cutting, there is simply no room for error. The precision and expertise of a skilled diamond cutter can make all the difference in creating a diamond that displays the perfect balance of fire, brilliance, and scintillation. Each cut and facet must be carefully calculated to maximize the diamond's beauty and value.

The role of a diamond cutter goes beyond simply shaping a rough diamond into a faceted gem. They are responsible for bringing out the full potential of the diamond, ensuring that it sparkles and shines with unmatched brilliance. A skilled diamond cutter knows how to work with the natural characteristics of the stone, enhancing its unique qualities and minimizing any imperfections.

The artistry and craftsmanship of a diamond cutter are evident in the final product. A well-cut diamond will have perfectly symmetrical facets, allowing light to enter and reflect back with maximum brilliance. It is this attention to detail and commitment to excellence that sets a skilled diamond cutter apart.

In addition to technical expertise, a skilled diamond cutter also possesses a deep passion for their craft. They understand the significance of the diamond they are working on, knowing that it will become a cherished symbol of love and commitment. Their dedication to creating a diamond that exceeds expectations is what makes them true masters of their trade.

In conclusion, a skilled diamond cutter is essential in the creation of a diamond that truly shines. Their expertise, precision, and passion are what transform a rough stone into a work of art. When choosing a diamond, it is important to recognize the importance of a skilled diamond cutter and the impact they have on the final product.

The Diamond Cutting Process

The diamond cutting process is a meticulous and intricate craft that requires the skill and expertise of a trained diamond cutter. Each step in the process is crucial to ensure that the diamond displays the perfect balance of fire, brilliance, and scintillation.

Step 1 - Mapping and Instructions

Before the diamond can be cut and polished, it undergoes a mapping process. A state-of-the-art diamond mapping machine is used to analyze and map the rough diamond. The results of this analysis are then handed to the diamond cutter, who follows strict instructions from the diamond assessor. These instructions outline the specific style, shape, and cut of the diamond.

Step 2 - Marking the Diamond

Once the diamond cutter receives the mapping results, they mark the rough diamond with ink to indicate where it will be cut. This step is crucial in determining the shape and size of the final diamond. The cutter uses a diamond tool called a tang to polish the stone, and depending on the size of the diamond, a cleaving or sawing process may be required to separate the rough diamond into two pieces.

Step 3 - Cleaving or Sawing

During this step, the diamond cutter either cleaves or saws the rough diamond into two separate pieces. The method used depends on the specific growth planes of the diamond. If the marking is along the line or parallel with the diamond, it is cleaved. If the marking is against the line, it needs to be sawed using a laser.

Step 4 - Bruting

After the sawing and cleaving process, the diamond undergoes a process called bruting or girdling. This step involves placing the diamond on a spinning axle and gradually rounding off the rough parts of the diamond until it is perfectly round. The bruting process is essential in creating the foundation of the diamond.

Step 5 - Polishing

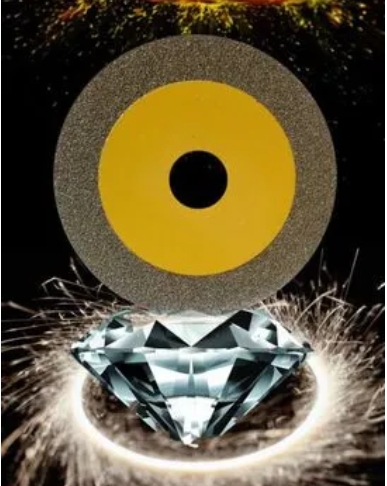

Polishing a diamond is a precise and skillful task that requires years of experience. The diamond cutter places the diamond on a rotating arm, known as a tang, and polishes it against a spinning wheel, called a scaife. This process smooths and gleams the diamond, bringing out its brilliance and fire. The cutter also polishes the remaining facets in the brilliant cut diamond, ensuring that each facet is cut in perfect proportion and symmetry.

The diamond cutting process is a labor-intensive and time-consuming art that requires dedication, attention to detail, and a deep understanding of the diamond's characteristics. It is through the expertise of a diamond cutter that a rough diamond is transformed into a stunning gemstone that will shine forever.

Step 1 - Mapping and Instructions

Mapping and instructions are crucial steps in the diamond cutting process. Before a diamond cutter begins cutting and polishing a rough diamond, it undergoes a thorough mapping process. This process involves analyzing and mapping the rough diamond using state-of-the-art diamond mapping machines. The results of this analysis are then handed to the diamond cutter, who follows strict instructions provided by the diamond assessor.

The mapping process determines the specific style, shape, and cut of the diamond. It provides the diamond cutter with valuable information about the rough diamond, including its unique characteristics and potential flaws. This information is essential for the cutter to create a diamond that displays the perfect balance of fire, brilliance, and scintillation.

The diamond cutter carefully studies the mapping results and instructions to develop a cutting and polishing plan that maximizes the potential of the rough diamond. This plan takes into consideration factors such as the size, shape, and quality of the diamond. The cutter aims to create a diamond that maximizes its true brilliance, prioritizing quality over size.

The mapping and instructions set the foundation for the diamond cutting process. They guide the cutter in determining the best approach to cut and shape the rough diamond, ensuring that every facet is cut with precision and accuracy. By following these instructions, the diamond cutter can create a diamond that meets the highest standards of beauty and value.

In summary, mapping and instructions are essential steps in the diamond cutting process. They provide the diamond cutter with crucial information and guidance, allowing them to create a diamond that showcases its unique beauty and brilliance. The expertise and attention to detail of the diamond cutter are instrumental in producing a diamond that will be cherished for a lifetime.

Step 2 - Marking the Diamond

Once the diamond cutter receives the mapping results, they embark on the crucial step of marking the diamond. This is where their expertise and artistic vision come into play. The cutter carefully examines the rough stone and determines the best way to cut and polish it to maximize its brilliance.

Using ink, the craftsman marks the diamond to indicate where it will be cut. This marking serves as a guide throughout the cutting and polishing process. The cutter then utilizes a diamond tool called a tang to begin the polishing process.

Depending on the size of the diamond, the cutter may need to undergo a cleaving or sawing process to separate the rough diamond into two pieces. This is done with precision and accuracy to ensure the best outcome for the final diamond.

The marking and cutting process is a delicate balance between preserving the diamond's natural beauty and maximizing its potential. The cutter's skill and experience are essential in determining the shape, size, and overall quality of the finished diamond.

By marking the diamond, the cutter sets the stage for the subsequent steps in the cutting and polishing process. Each mark made by the cutter carries the weight of their expertise and knowledge, as they strive to create a diamond that will dazzle with fire, brilliance, and scintillation.

In the hands of a skilled diamond cutter, the marking of the diamond is more than just a technical step; it is an art form that requires precision, attention to detail, and a deep understanding of the diamond's potential.

Step 3 - Cleaving or Sawing

Cleaving or sawing is a crucial step in the diamond cutting process. Once the diamond cutter receives the mapping results and marks the diamond, it is time to separate the rough diamond into two separate pieces. This is done through either cleaving or sawing, depending on the different growth planes on the stone.

Cleaving is the process of splitting the diamond along a predetermined line or parallel with the diamond. It requires precision and skill to ensure a clean and accurate split. On the other hand, if the marking is against the line, the diamond needs to be sawed using a laser. This method utilizes the latest technology to cut the diamond in two pieces with speed and accuracy.

The choice between cleaving and sawing depends on the specific characteristics of the rough diamond and the desired outcome. The diamond cutter carefully evaluates the growth planes and markings to determine the most appropriate method. Both cleaving and sawing require expertise and experience to ensure that the diamond is split accurately without compromising its value and brilliance.

After the cleaving or sawing process, the diamond is ready for the next step in the cutting process. The separated pieces will undergo further shaping and polishing to bring out the diamond's fire, brilliance, and scintillation. Each cut and decision made during the cleaving or sawing process plays a significant role in determining the final outcome of the diamond.

In the hands of a skilled diamond cutter, cleaving or sawing is a delicate and precise process that sets the foundation for creating a stunning and valuable diamond. It requires a deep understanding of the diamond's structure and the ability to make calculated decisions to maximize the diamond's potential.

Step 4 - Bruting

Bruting is a crucial step in the diamond cutting process that takes a rough diamond and transforms it into a perfectly round gem. This process requires precision and skill to achieve the desired shape and symmetry.

To begin bruting, the diamond is placed on a spinning axle, which rotates two stones in opposite directions at high speed. This motion gradually rounds off the rough parts of the diamond, resulting in a perfectly round shape. The goal is to create a girdle that is smooth and symmetrical.

During this process, the diamond cutter must pay close attention to detail and ensure that the diamond is bruted to the correct specifications. The symmetry of the stone is established by creating a set of facets on the table, crown, pavilion, and culet. These facets play a crucial role in the overall brilliance and fire of the diamond.

Bruting is a delicate and time-consuming process that requires patience and expertise. The diamond cutter must have a deep understanding of the diamond's structure and how to manipulate it to achieve the desired shape. Any mistakes or miscalculations during bruting can result in a loss of diamond weight and affect the overall value of the stone.

After the bruting process is complete, the diamond moves on to the next step in the cutting and polishing process. Each stage of diamond cutting requires the utmost care and attention to detail, ensuring that the final product is a diamond that displays the perfect balance of fire, brilliance, and scintillation.

In conclusion, bruting is a critical step in the diamond cutting process that transforms a rough diamond into a perfectly round gem. It requires the expertise and skill of a talented diamond cutter to achieve the desired shape and symmetry. With precision and attention to detail, the diamond cutter ensures that the diamond reaches its full potential and shines with maximum brilliance.

Step 5 - Polishing

Polishing a diamond is the final and most crucial step in the diamond cutting process. It requires extreme precision and years of experience for a diamond cutter to perfect. This is where a rough diamond is transformed into a beautiful faceted gemstone with fire, brilliance, and scintillation.

To begin the polishing process, the diamond cutter places the diamond on a rotating arm called a tang, and puts it against a spinning wheel known as a scaife. This allows the rough stone to be polished into a smooth and gleaming gem. The cutter carefully shapes and polishes each facet of the diamond to ensure maximum brilliance and sparkle.

After the initial polishing, the diamond goes through two additional important steps: blocking and brillianteering. During the blocking stage, the cutter polishes the facets onto the diamond, establishing the symmetry of the stone. This involves creating the set of facets on the table, crown, pavilion, and culet. Once the blocking stage is complete, the diamond is often referred to as a "single cut" diamond.

The final step, brillianteering, involves polishing the remaining facets in the brilliant cut diamond. A round brilliant cut diamond will have a total of 57 facets, all of which need to be cut with perfect proportion and symmetry to achieve maximum brilliance. It is crucial for the diamond cutter to get the process right the first time, as any corrections made result in a loss of diamond weight, which can affect the overall value of the diamond.

In conclusion, the polishing stage is where a diamond truly comes to life. It is the skill and expertise of the diamond cutter that ensures the diamond displays its full potential in terms of fire, brilliance, and scintillation. The years of training and dedication that a diamond cutter undergoes are essential in creating a diamond that will shine forever.

The Role of a Diamond Cutter

The role of a diamond cutter is not just about cutting and shaping diamonds; it is a true art form that requires years of experience and expertise. A skilled diamond cutter is responsible for transforming a rough diamond into a stunning faceted gemstone that displays the perfect balance of fire, brilliance, and scintillation. Their craftsmanship and attention to detail are what make a diamond truly shine.

A diamond cutter's role begins with following instructions and mapping the rough diamond. They carefully analyze the diamond and determine the specific style, shape, and cut that will maximize its brilliance. This mapping process is crucial as it sets the foundation for the entire cutting and polishing process.

Once the diamond is mapped, the cutter marks the gemstone with ink, indicating where it will be cut. This step requires precision and expertise, as the cutter must consider the diamond's size, shape, and the desired outcome. They may have to undergo a cleaving or sawing process to separate the rough diamond into two pieces.

After the diamond is separated, the cutter moves on to bruting, which involves rounding off the rough parts of the diamond to achieve a perfectly round shape. This step requires the use of specialized tools and techniques to ensure the diamond's symmetry and balance.

Finally, the diamond cutter proceeds to the polishing stage, where they use a rotating arm and a spinning wheel to polish the diamond into a smooth and gleaming gem. This process requires extreme precision and skill, as each facet must be cut in perfect proportion and symmetry to maximize the diamond's brilliance.

Throughout the entire process, a diamond cutter must exercise their expertise and artistic vision to bring out the full potential of the diamond. They must also adhere to strict quality standards and ensure that each facet is polished to perfection. Their role is not just about cutting and shaping diamonds; it is about creating a masterpiece that will be cherished for a lifetime.

In conclusion, the role of a diamond cutter is a highly skilled and specialized profession that requires years of training and experience. Their expertise and attention to detail are what transform a rough diamond into a dazzling gemstone. A diamond cutter's role is not just about cutting and shaping; it is about creating a work of art that will be treasured for generations to come.

-All diamond tools can be ordered and fabricated!

-Henry Wang | Quote Manager

-WhatsApp:+86-18030177538

-Email: ceo@zdiamondtools.com

-Web www.zdiamondtools.com