The Benefits of Using Diamond Grinding Discs

Introduction

Welcome to our article on the benefits of using diamond grinding discs. If you're looking for a reliable and efficient tool for grinding, deburring, surface prepping, or cutting various materials, diamond grinding discs are the answer. These discs are specifically designed for heavy-duty material removal applications on metals like cast iron, steel, stainless steel, non-ferrous metals, metal alloys, and even carbon fiber reinforcement.

Unlike traditional grinding discs, diamond grinding discs offer exceptional performance and durability. They are constructed with robust diamonds and bonds, which not only provide minimal vibration and noise but also ensure a longer lifespan compared to standard grinding wheels. With their vacuum-brazed diamond and solid steel construction, these discs won't explode or shatter during grinding, making them a safer option for your projects.

In this article, we will explore the various applications of diamond grinding discs, the different types available, and the advantages they offer over conventional grinding wheels. We will also provide some useful tips for using diamond grinding discs effectively. Whether you're a professional in the metalworking industry or a DIY enthusiast, this article will serve as your guide to understanding the power and versatility of diamond grinding discs.

So, let's dive into the world of diamond grinding discs and discover how they can revolutionize your grinding, cutting, and surface prepping tasks. Get ready to experience faster cutting, increased productivity, and superior results with these remarkable tools.

Section 1: What are Diamond Grinding Discs?

Diamond grinding discs are a type of abrasive tool that is specifically designed for heavy-duty material removal applications on metals such as cast iron, steel, stainless steel, non-ferrous metals, metal alloys, and carbon fiber reinforcement. These discs are made with robust diamonds and bonds, which allow them to effectively grind these materials with minimal vibration and noise.

Unlike traditional grinding wheels, diamond grinding discs utilize a unique core bonding technology that increases their lifespan by exposing the full diamond particles. This technology not only ensures maximum grinding performance but also reduces sparks, odor, and debris during the grinding process.

One of the key advantages of diamond grinding discs is their versatility. They can be used not only on steel and other metals but also on green and reinforced concrete, PVC, plastic, brick, paving brick, block, and stone. This makes them an ideal tool for various industries, including foundries and water departments, as well as anyone who needs to grind metal.

Furthermore, diamond grinding discs offer several benefits over conventional abrasive discs. They do not emit hazardous particles or fibers during cutting, making them a healthier option to use. Additionally, these discs can be used for multiple purposes, including grinding, deburring, surface prepping, cutting sheet metal, and even fiberglass.

Overall, diamond grinding discs are a reliable and efficient tool for professionals and DIY enthusiasts alike. Their durability, versatility, and superior performance make them an essential component in any metalworking or material removal project.

Section 2: Applications of Diamond Grinding Discs

When it comes to grinding metal and steel, diamond grinding discs offer a wide range of applications. These versatile tools are designed for heavy-duty material removal on various metals, including cast iron, stainless steel, and non-ferrous metals.

One of the primary applications of diamond grinding discs is in the foundry industry. Foundries often require the grinding of metal components to smooth rough surfaces, remove excess material, or prepare the surface for further processing. Diamond grinding discs are ideal for this task due to their robust diamonds and bonds, which allow for efficient and precise grinding with minimal vibration and noise.

In addition to foundries, diamond grinding discs are also widely used in water departments and other industries that deal with metal grinding. These discs can effectively grind steel, iron, and other metals, making them indispensable tools for metalworking and maintenance tasks.

Moreover, diamond grinding discs are not limited to metal applications. They can also be used on green and reinforced concrete, PVC, plastic, brick, paving brick, block, and stone. This versatility makes diamond grinding discs a valuable tool for construction and renovation projects, where different materials need to be ground or leveled.

Overall, diamond grinding discs offer a reliable and efficient solution for a wide range of applications. Their durability, versatility, and ability to grind various materials make them a preferred choice for professionals in industries such as foundries, water departments, and construction. Whether it's grinding metal components or leveling concrete surfaces, diamond grinding discs provide unmatched performance and quality.

Section 3: Types of Diamond Grinding Discs

When it comes to diamond grinding discs, there are various types available in the market to suit different applications and materials. Each type offers unique features and benefits that cater to specific grinding needs. Here, we will explore some of the most common types of diamond grinding discs:

Metal-bonded diamond grinding discs: These discs are known for their exceptional durability and long lifespan. They are designed with metal bonds that securely hold the diamond particles in place, making them ideal for heavy-duty grinding tasks on materials like concrete, stone, and metal alloys. Metal-bonded discs are highly efficient in removing material and provide excellent results.

Resin-bonded diamond grinding discs: Resin-bonded discs are known for their versatility and ability to deliver smooth and precise finishes. They are commonly used for grinding and polishing applications on materials like granite, marble, and glass. The resin bond allows for better control and precision during the grinding process, resulting in superior surface quality.

Electroplated diamond grinding discs: These discs are unique in their construction, with diamond particles electroplated onto the disc's surface. They are widely used for grinding and shaping various materials, including ceramics, composites, and fiberglass. Electroplated discs offer exceptional cutting performance and are known for their ability to maintain a consistent cutting edge.

Hybrid diamond grinding discs: Hybrid discs combine the best features of both metal-bonded and resin-bonded discs. They are designed to provide high material removal rates while also delivering a smooth finish. Hybrid discs are commonly used in applications where both aggressive grinding and fine finishing are required, such as in the automotive and aerospace industries.

Segmented diamond grinding discs: These discs feature segmented designs with multiple diamond segments attached to the disc's surface. They are particularly effective in grinding uneven surfaces and removing coatings or adhesives. Segmented discs are commonly used in concrete grinding applications, where they provide efficient material removal and excellent surface preparation.

It is important to choose the right type of diamond grinding disc based on the specific material and application requirements. By selecting the appropriate disc, users can achieve optimal results in terms of grinding efficiency, surface quality, and overall productivity.

Section 4: Advantages of Diamond Grinding Discs

Diamond grinding discs offer a multitude of advantages that make them a preferred choice for various applications. Here are some key advantages of using diamond grinding discs:

Unmatched Durability: Diamond grinding discs are known for their exceptional durability. The diamond particles embedded in the disc provide superior hardness, allowing them to withstand heavy-duty grinding tasks without wearing out quickly. This durability ensures longer disc life, reducing the need for frequent replacements and saving both time and money.

Efficient Material Removal: With their robust diamond particles and bonds, diamond grinding discs excel in material removal. They are designed to grind metals, including cast iron, steel, stainless steel, and non-ferrous metals, with minimal vibration and noise. This efficient material removal capability enables faster and more effective grinding, increasing productivity.

Versatility: Diamond grinding discs offer versatility in terms of applications. They can be used for various tasks, such as grinding, deburring, surface prepping, and cutting sheet metal, fiberglass, and more. The availability of different cutting areas on each wheel further enhances their versatility, allowing for unmatched access and adaptability across countless applications.

Safety: Safety is a paramount concern in any grinding operation, and diamond grinding discs prioritize safety. Unlike conventional grinding wheels, diamond grinding discs do not emit hazardous particles or fibers during cutting. Additionally, their vacuum-brazed diamond and solid steel construction ensures that they won't explode or shatter during grinding, providing a safer working environment.

Time and Cost Savings: Diamond grinding discs offer significant time and cost savings. Their core bonding technology increases wheel life by exposing the full diamond particles, maximizing grinding performance and reducing the need for frequent replacements. This extended lifespan, coupled with their efficient material removal capabilities, allows for faster grinding, ultimately saving time and reducing labor costs.

In conclusion, diamond grinding discs offer unparalleled advantages in terms of durability, material removal, versatility, safety, and time and cost savings. Their superior performance and reliability make them an indispensable tool in various industries and applications.

Section 5: Tips for Using Diamond Grinding Discs

When it comes to using diamond grinding discs, there are a few tips and tricks that can help you achieve the best results. Whether you are a professional or a DIY enthusiast, these tips will ensure that you make the most out of your grinding disc.

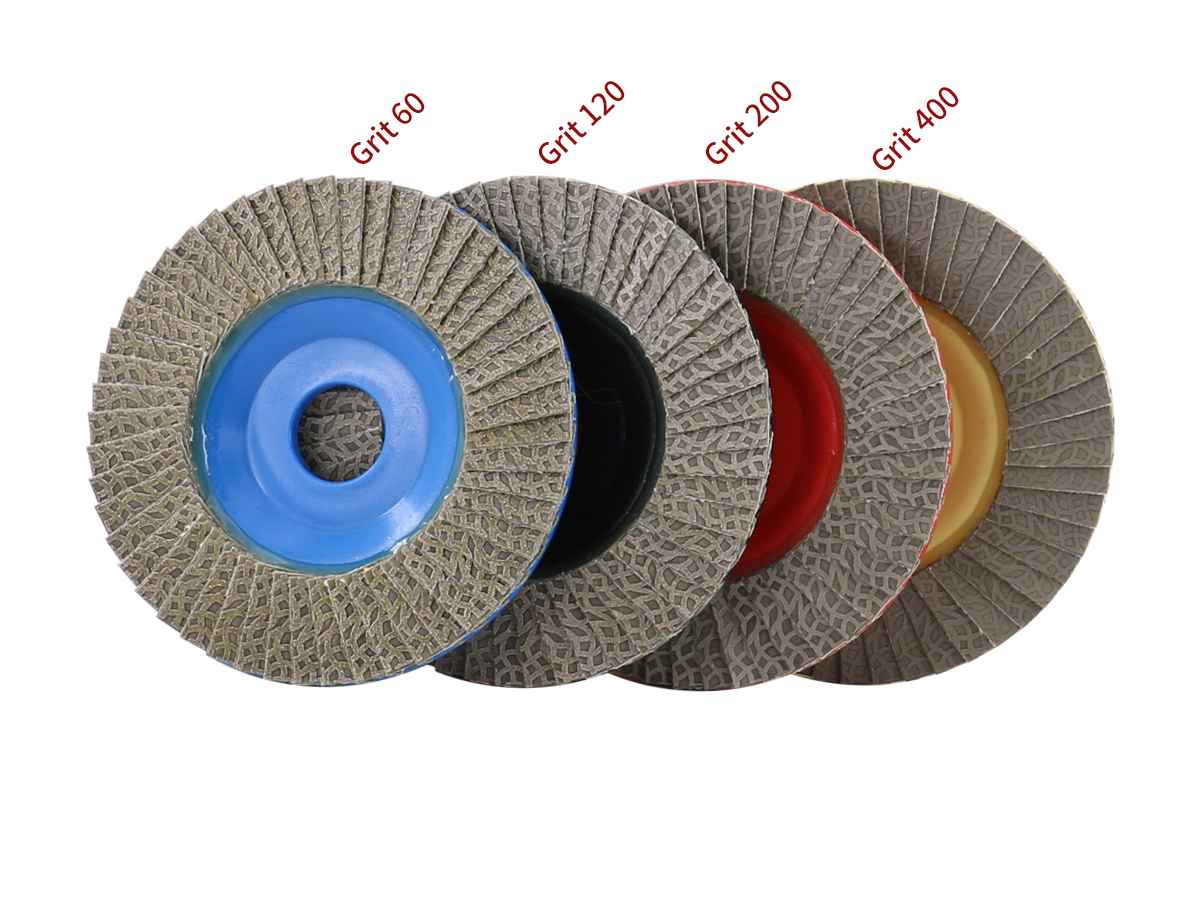

Choose the right disc for the job: Diamond grinding discs come in various sizes and grits, so it's important to select the right one for your specific application. Consider the material you are grinding and the desired finish to determine the appropriate disc.

Keep the disc lubricated: Using water or coolant while grinding with a diamond disc can help to keep the surface lubricated, reducing friction and preventing overheating. This not only extends the life of the disc but also ensures a smoother grinding process.

Apply light pressure: It's important to let the diamonds on the disc do the work for you. Applying excessive pressure can cause the disc to wear out quickly and may result in uneven grinding. Instead, use light pressure and let the disc glide smoothly over the surface.

Use the right technique: When using a diamond grinding disc, it's important to maintain a consistent grinding motion. Avoid stopping and starting abruptly, as this can leave marks on the surface. Instead, use a steady and continuous motion for a uniform finish.

Protect yourself: Grinding metal can produce sparks and debris, so it's crucial to wear appropriate protective gear. This includes safety glasses, gloves, and a dust mask to protect your eyes, hands, and lungs from potential hazards.

By following these tips, you can ensure that you get the most out of your diamond grinding disc. Remember to choose the right disc for the job, keep it lubricated, apply light pressure, use the correct technique, and prioritize safety. With these guidelines in mind, you can achieve professional-quality results and tackle any grinding task with confidence.

-All diamond tools can be ordered and fabricated!

-Henry Wang | Quote Manager

-WhatsApp:+86-18030177538

-Email: ceo@zdiamondtools.com

-Web www.zdiamondtools.com

Company Profile