You could use a ceramic cutting saw blade used on ceramic cutting machine, whose motor directly drive saw blade for ceramic cutting machine. By the rapid speed of motor, saw blade is driven for high-speed line cutting so as to achieve the good cutting result for ceramic which is a higher hardness of the decorative material, without any collapse.

Methods as below:

1. Straight cut

Adjusting the cutting head to make the blade and the table vertical, and fix the blade angle through the locking handle. Saw blade position could be adjusted through a pair of limit bolts . Then put the stone or other building materials on the table, open the switch, the blade rotation, the pump began to fetch water, push the table forward so that the blade cut the material on the table as required.

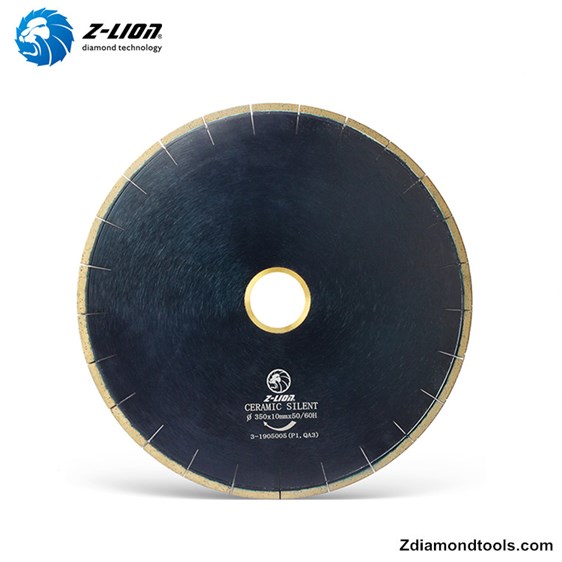

Mesh Turbo Cutter.JPG

2. 45 ° chamfer cutting

The machine has a rotatable cutting head, you can do 45 degrees cutting, please firstly turn the head rotation to 45 degrees, tighten the locking handle, so that the blade at the cutting material to promote the table can move forward 45 degree cutting.

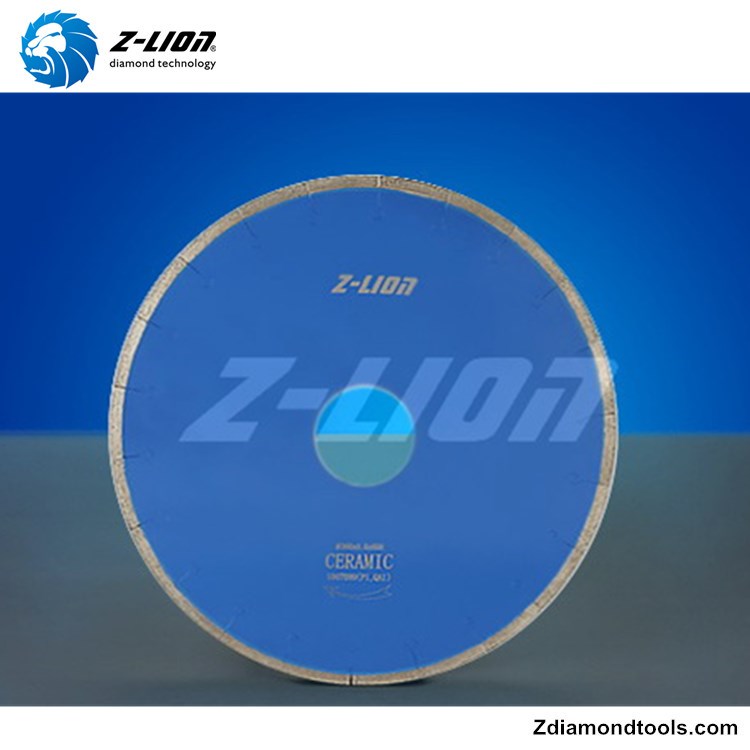

x segment blade for porcelain tile.JPG

Maintenance and precautions

1. Be sure to disconnect the power supply at any time, during maintenance and repair.

2. Ceramic cutting machine using the tool is a diamond saw blade, the blade can not cut metal materials, can not cut the curve casually.

3. When replacing a new blade, check the blade for cracks, notches, and bends.

4. A blunt saw blade will lead to the motor not work regularlly. You should replace new cutting blade on time. Otherwise, you should use a refractory brick cutting knife method.

5. Cutting machine motor is S6 work system, when the motor in the use come up with automatic shutdown, it means the motor automatically protect the work, please disable ten minutes, then open the switch and the motor can work.

6. Pay attention to power ground, children are prohibited to boot operation.

7. Regularly check the machine's safety shield and other parts which are easy to be loose.

8. Regularly replace saw blades, blunt saw blades can damage the motor and affect the machine's cutting quality and efficiency.

9. Be sure to avoid prolonged exposure of wires and electrical components to water or moisture. Keep all parts dry.

10. After every time use, you need to let go of the water in the basin as well as clean the basin. Because it is with water operations, the parts of the machine should be dry to prevent rust.

11. After each time use, use water to clean the pump tubing and filter cotton to ensure smooth flow. If the pump can not release water normally, please contact the supplier immediately for replacement. Such type of machine is strictly prohibited cutting!

12. Periodically check the fasteners of various parts of the machine to ensure fastening.

-All diamond tools can be ordered and fabricated!

- Henry Wang | Quote Manager

Henry Wang | Quote Manager

-WhatsApp:+86-13459035657

-Email: ceo@zdiamondtools.com

-Web www.zdiamondtools.com

Company Profile

Certifications

Company Team

Exhibition

Logistics

FAQ