Buff polishing pads | This buff polishing pad is good for stone polishing,granite, marble, quartz etc, you can use it without water, will have a little dust when polish, also you can put some water,this type have a good sale in USA and Eu

Brand:

Z-LIONItem No.:

ZL-BUFF-123D BlackMin. Order:

10PCSPayment Terms:

T/T, L/C,Paypal,Western Union, etc.Shipping Port:

Xiamen Port.Delivery Time:

3-14 Days after payment comfirm, according to quantity.Usage:

good for stone granite marble polishingSupply Ability:

10,000 piece/month.Origin:

ChinaCatalog:

Flexible Polishing Pads

ZL-BUFF-123D 100mm 4inch Diamond Dry Black Buffing Polishing Pads for Granite Marble Stone Polishing

|

Brand

|

Z-LION

|

|

Size

|

4 inch / 100mm

|

|

Thickness

|

2.5mm

|

|

Material

|

Resin bond+diamond grain

|

|

Application

|

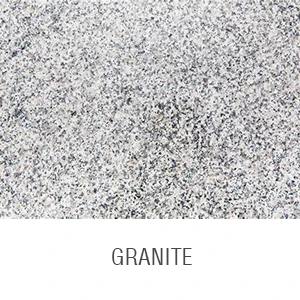

Granite, marble, quartz, sandstone, terrazzo., etc polishing

|

Advantages:

a) High efficiency :For each stone our engineer designed the special pads to suit, it can have a more fast polishipng with a high gloss.

b) Nice surface:Not marks on the stone when polishing and not burns the surface to change natural color, and also no water mark.

c) Good quality: Bright clear light and have a long use time for stone polishing pads.

d) High quality backed make it hard to left when working.

We have our own factory so it's easy to infrom you the delivery time, and 100% re-check will provide the good quality polishing pads to you.

Different grits polishing pads we produced in defferent color to distinction.

Buffing polishing pad Application:

Using buff polishing pads correctly is essential to achieve the best results and protect the surface of your vehicle. Follow these steps to ensure a successful buffing process:

Prepare the Surface: Before using the buff polishing pad, thoroughly clean the surface of your vehicle to remove any dirt, debris, or contaminants. This will prevent scratches and ensure a smooth buffing process.

Choose the Right Pad: Select the appropriate buff polishing pad for the task at hand. Consider factors such as the type of paint, the severity of imperfections, and the desired level of polishing. Different pads offer varying levels of cutting, polishing, and finishing capabilities.

Apply the Buffing Compound: Apply a small amount of buffing compound to the pad. Start with a low-speed setting to spread the compound evenly across the surface. Gradually increase the speed as needed, keeping in mind the recommended RPM range for the specific pad and compound.

Buff in Sections: Divide the surface into manageable sections and work on one section at a time. Apply light to moderate pressure and move the pad in overlapping, circular motions. Avoid staying in one spot for too long, as this can lead to uneven results.

Monitor the Progress: Regularly check the surface to assess the progress and adjust your technique if necessary. If the pad becomes clogged with residue, clean it or replace it with a fresh pad to maintain optimal performance.

Finishing Touches: Once you have achieved the desired level of correction or polishing, switch to a finishing pad for a final pass. This will enhance the shine and smoothness of the surface.

Clean and Maintain the Pads: After each use, clean the buff polishing pads according to the manufacturer's instructions. Proper maintenance will prolong the lifespan of the pads and ensure consistent performance.

Remember to always follow safety precautions, such as wearing protective eyewear and gloves, and using the appropriate tools and equipment. With the right technique and the best buff polishing pads, you can achieve professional-quality results and restore the beauty of your vehicle's paintwork.

Taking proper care of your buff polishing pads is essential to ensure their longevity and maintain their performance. Here are some tips to help you keep your pads in top condition:

Clean your pads regularly: After each use, it is important to clean your buff polishing pads to remove any residue or compounds that may have accumulated. Use a dedicated pad cleaner or follow the manufacturer's instructions for cleaning. This will help prevent buildup and maintain the effectiveness of the pads.

Machine wash when necessary: Some buff polishing pads are machine washable, which makes cleaning them easier. If your pads are machine washable, follow the recommended washing instructions. Be sure to use a gentle cycle and mild detergent to avoid damaging the pads.

Air dry the pads: After cleaning, allow your buff polishing pads to air dry completely before storing or using them again. Avoid using heat or direct sunlight to dry the pads, as this can cause them to warp or deteriorate.

Inspect for damage: Regularly inspect your buff polishing pads for any signs of wear or damage. Look for fraying edges, tears, or excessive wear. If you notice any damage, it is best to replace the pad to maintain optimal performance.

Store properly: When not in use, store your buff polishing pads in a clean and dry area. Avoid placing heavy objects on top of the pads, as this can deform or flatten them. Consider using a storage case or bag to protect the pads from dust and debris.

By following these care tips, you can extend the lifespan of your buff polishing pads and ensure they continue to deliver excellent results. Remember to always refer to the manufacturer's instructions for specific care guidelines for your pads.

-All diamond tools can be ordered and fabricated!

-Henry Wang | Quote Manager

-WhatsApp:+86-13459035657

-Email: ceo@zdiamondtools.com

-Web www.zdiamondtools.com

Company Profile

Global Renowned Polishing Tool Innovative Enterprise.

Global Renowned Polishing Tool Innovative Enterprise.

|

Registered Add |

No.25 Northwest,Xiangyue Road,Xiang'an Industrial District,Torch Hi-New Zone,Xiamen,Fujian,China. |

|---|---|

|

Main Market |

North America, Europe, Middle East and South America,etc. |

|

Brand |

Z Lion |

|

Number of Employees |

100-200 |

|

Established in |

2002 |

☺ 1.Enterprise Qualification:

✔New Three Board listed enterprise

✔National intellectual property advantage enterprise

✔63 of Domesticand International patents

✔Innovative enterprise of Fujian

✔Drafting and formulating units of "diamond flexible polishing sheet"

☺ 2.Professional Diamond Tool Manufacturer:

✔ Direct Factory Price

✔ 18+ Years Stone Experience Since 2002

✔ 100+ Cooperative Factories

✔ 8000 M2 Factories

☺ Trustworthy Diamond Tools Provider

✔ 20+ Professional Agents In Various Countries

✔ 80+ Exporting Countries

✔ 150+ Workers and Sales Team

✔ 300+ Active Customers

✔Production is run strictly sticking to ISO 9001:2008 quality system, which makes us leading place in efficiency and quality within the industry.

✔Our entire ISO9001 quality management system production process includes raw material testing, production site inspection, finished product inspection, product testing, packaging, etc.

✔Our R&D and workers are all with rich experience for producing products with high accuracy and the material is with special made by our engineers.

✔Contact us, you will get more than what you see.

next:NO

You can contact us any way that is convenient for you. We are available 24/7 via fax, email or telephone.