Z-LION,Global Renowned Innovative China Hybrid diamond flap wheels,Hybrid flap wheels Manufacturers, Suppliers.All Hybrid diamond flap wheels products are with high quality and competitive price.

Brand:

Z-LIONItem No.:

ZL-WMC67PHMin. Order:

One Piece & Any amount order is available. it would be much better if the weight reachs 45kgs(requested by AirLine Companies,Otherwise the Airfreight below 45kgs is very high).Payment Terms:

T/T, L/C,Paypal,Western Union, etc.Shipping Port:

Xiamen Port.Delivery Time:

3-14 Days after payment comfirm, according to quantity.Usage:

Widely used for grinding, shaping, beveling and polishing edges on natural stone, engineered stone, porcelain stoneware as well as concrete, terrazzo, tile, etc.Supply Ability:

10,000 piece/month.Origin:

Xiamen, China.Catalog:

Diamond Flap Disc

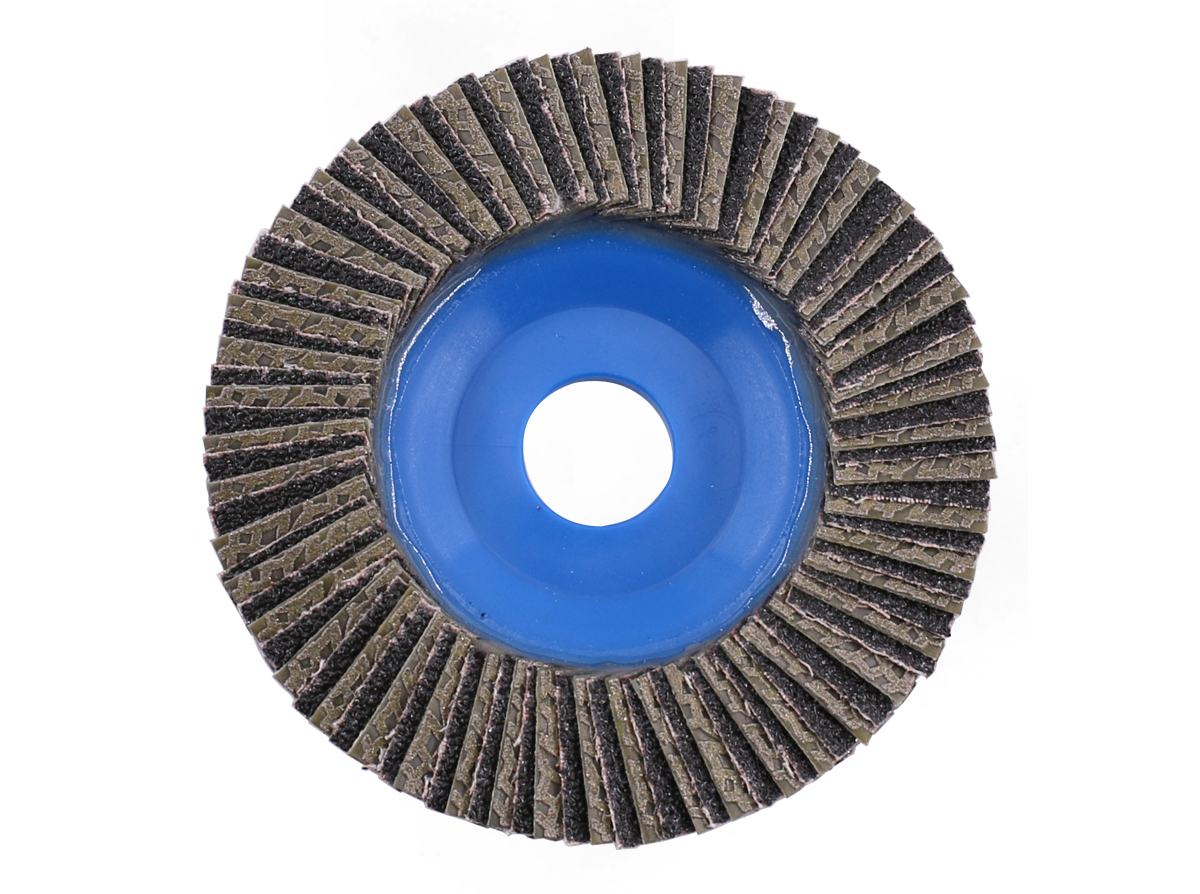

ZL-WMC67PH Plastic Backing Hybrid Diamond Flap Wheels for Porcelain Tile Grinding

Z-LION have been engaged in developing and manufacturing of electroplated diamond sheets and strips since its establishment. Electroplated diamond sheets and strips can be made into all kinds of tools such as foam backed hand pads, flap discs, diamond belts, velcro backed polishing pads, Hybrid Hybrid Diamond flap wheels,adhesive or magnet polishing discs, Roloc pads, polishing drums, etc. Those tools are widely used for sanding, grinding and polishing of stone, glass, ceramic, superhard coatings, composites, textiles, etc.

• Combination of diamond flaps and silicon carbide flaps to offer better cost performance.

• Dense overlapping flaps increase elasticity of the flap disc also provide longer tool life.

• The elasticity of the flap disc is advantageous for smooth sanding without vibration.

• Reinforced plastic backer to reduce the possibility of backing breakage and increase the safety of the flap disc.

• Special interior design and high quality glue to prevent flap separation.

Hybrid diamond flap wheels Used for grinding and trimming of stone, concrete, glass, ceramics, steel, synthetic material, alloy materials, monocrystalline and polycrystalline silicon, superalloy, etc.

| Product Name: | Hybrid diamond flap wheels |

| Item No.: | ZL-WMC67PH |

| Brand: | Z-LION |

| Working surface: | Electroplated flexible diamond sheet and silicon carbide sheet |

| Features of the product: | • Combination of diamond flaps and silicon carbide flaps to offer better cost performance. • Dense overlapping flaps increase elasticity of the flap disc also provide longer tool life. • The elasticity of the flap disc is advantageous for smooth sanding without vibration. • Reinforced plastic backer to reduce the possibility of backing breakage and increase the safety of the flap disc. • Special interior design and high quality glue to prevent flap separation. |

| Available size: | 4.5" |

| Popular grits: | 60# 120# 200# 400# |

| Available grits: | 60# 120# 200# 400# 600# 1000# 2000# 3000# |

| Flaps: | 50% of diamond flaps and 50% of silicon carbide flaps |

| Base: | Plastic backing in blue, black, red, yellow |

| Usage: | Wet and dry |

| Applied machine: | Angle grinders |

| Applications: | Used for grinding, shaping, beveling and polishing edges on natural stone, engineered stone, porcelain stoneware as well as concrete, terrazzo, tile, etc. |

Hybrid diamond flap wheels

Compared with the cup wheel, our diamond disc provides smooth and uniform grinding, provides protection for the operator, and significantly reduces hand and arm vibration! The service life has been increased by more than 100 times, making it more durable and efficient.

Hybrid diamond flap wheels Specification:

The Hybrid diamond flap wheels are designed for fast material removal applications on all hard, brittle materials without the need for high pressure. This flap disc comes with a combination of diamond and silicon carbide flaps on a reinforced plastic backer pad. Each flap makes line contact so that the disc will maintain fast, aggressive cutting without having to apply pressure. Although it is designed for high-speed angle grinders, for the best results, We recommends using at 8,000 rpm if the grinder has a variable-speed control switch. While the Flap Disc is great for dry use, it can be used wet to keep the dust down, for higher performance and a longer life.

In general, you’re better off using a flap disc when abrading metal and applying a smoother finish. Although they’ve long been used with high-speed angle grinders, advances in both design and materials have brought flap discs to the point where they can carry out grinding, blending, and finishing jobs much more quickly and with less noise than grinding wheels- layered flaps constantly expose new grain and act as a cushion, resulting in less noise and vibration.

Other advantages include:

Grinding wheels can play an important role in your project, particularly during material removal, but when you’re working with metal and need a tool that can achieve results during each stage of the project, flap discs may be your best and most efficient option.

The Company Profile of Xiamen ZL Diamond Technology Co., Ltd.

Z-LION (short for Xiamen ZL Diamond Technology Co., Ltd.) is a professional manufacturer of diamond tools in Xiamen, China. Established in 2002 and listed in New Third Board as a public company in 2015.

Z-LION have been engaged in developing and manufacturing of electroplated diamond sheets and strips since its establishment. Electroplated diamond sheets and strips can be made into all kinds of tools such as foam backed hand pads, flap discs, diamond belts, velcro backed polishing pads, adhesive or magnet polishing discs, Roloc pads, polishing drums, etc. Those tools are widely used for sanding, grinding and polishing of stone, glass, ceramic, superhard coatings, composites, textiles, etc.

Z-LION attach much importance to innovation. We are honored as” National Intellectual Property Advantage Enterprise”, “Fujian Innovative Enterprises”. We own 63 of domestic and international patents. And we are setter of “Diamond Flexible Polishing Pads Industrial Standard”.

Z-LION always do our best to keep close to customers. We have attended more than 100 exhibitions all over the world. Face to face meeting with customers in the exhibitions helped us to find out which kind of diamond tools will make polishing more efficient, so that we can keep updating our existing products and developing new products. Our products are loved by our customers especially in Europe, North and South American and Australia.

-All diamond tools can be ordered and fabricated!

-Henry Wang | Quote Manager

-WhatsApp:+86-18030177538

-Email: ceo@zdiamondtools.com

-Web www.zdiamondtools.com

Company Profile

next:NO

You can contact us any way that is convenient for you. We are available 24/7 via fax, email or telephone.