Flap Grinder Disc | Z-LION,Global Renowned Innovative China flap grinder disc Manufacturers, Suppliers.All flap grinder disc products are with high quality and competitive price.

Brand:

Z-LIONItem No.:

ZL-WMC67YMin. Order:

10PCSPayment Terms:

T/T, L/C,Paypal,Western Union, etc.Shipping Port:

Xiamen Port.Delivery Time:

3-14 Days after payment comfirm, according to quantity.Usage:

good used for Engineered Quartz GrindingSupply Ability:

10,000 piece/month.Origin:

ChinaCatalog:

Quartz Tools

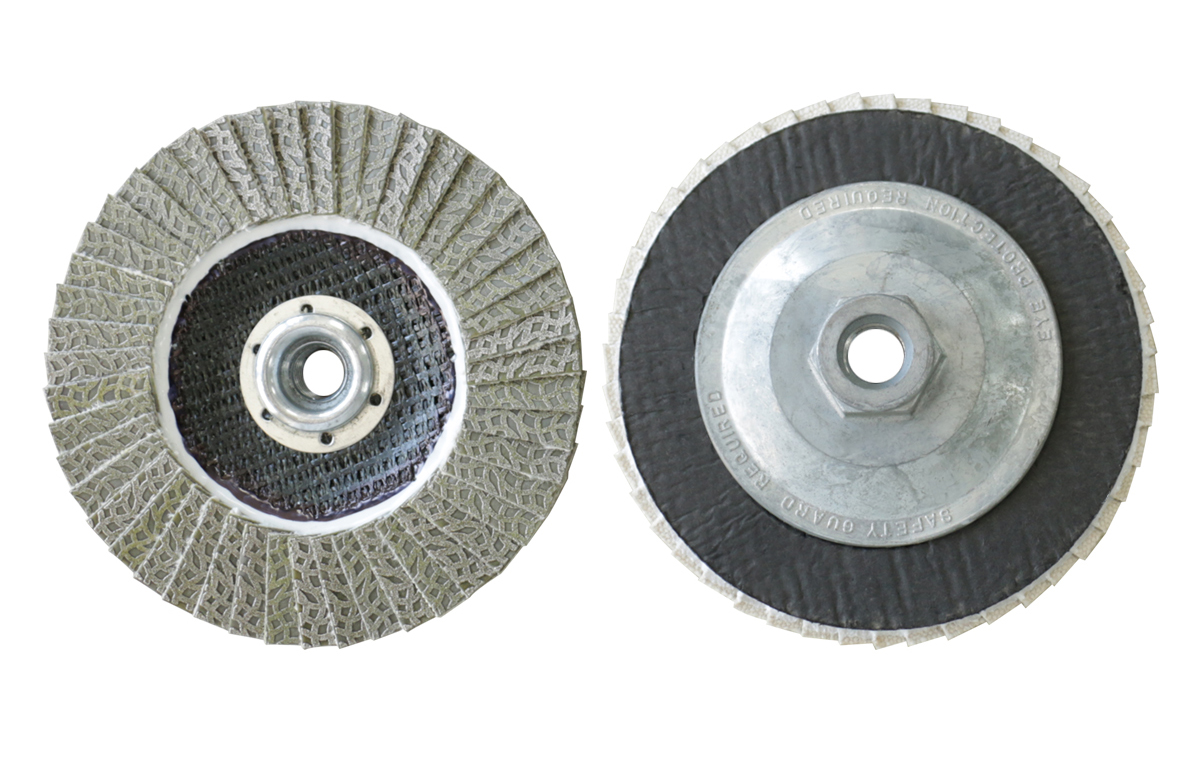

ZL-WMC67Y 5inch Electroplated Diamond Flap Grinder Disc for Engineered Quartz Grinding With M14 or 5/8-11 Thread

Z-LION have been engaged in developing and manufacturing of electroplated diamond sheets and strips since its establishment. Electroplated diamond sheets and strips can be made into all kinds of tools such as foam backed hand pads, flap discs, diamond belts, velcro backed polishing pads, adhesive or magnet polishing discs, Roloc pads, polishing drums, etc. Those tools are widely used for sanding, grinding and polishing of stone, glass, ceramic, superhard coatings, composites, textiles, etc.

• Flap Grinder Disc can be an ideal replacement of cup wheels for concrete polishers doing edge work, as it has high stock removal rate but is much lighter than heavy cup wheels.

• Aluminum M14 or 5/8-11 thread also helps to reduce the tool weight.

• Compare to cup wheels, flap discs offer smoother grinding, significantly reduce hand and arm vibration of operators.

• Diamond flaps continually expose new layers as the upper flaps wear to deliver consistent cut rate and longer tool life.

Flap Grinder Disc Used for grinding and trimming of stone, concrete, glass, ceramics, steel, synthetic material, alloy materials, monocrystalline and polycrystalline silicon, superalloy, etc.

| Product Name: | Fiberglass backing diamond Flap Grinder Disc with M14 or 5/8-11 thread |

| Item No.: | ZL-WMC67Y |

| Brand: | Z-LION |

| Working surface: | Electroplated flexible diamond sheet |

| Features of the product: | • Grinder flap disc can be an ideal replacement of cup wheels for concrete polishers doing edge work, as it has high stock removal rate but is much lighter than heavy cup wheels. • Aluminum M14 or 5/8-11 thread also helps to reduce the tool weight. • Compare to cup wheels, flap discs offer smoother grinding, significantly reduce hand and arm vibration of operators. • Diamond flaps continually expose new layers as the upper flaps wear to deliver consistent cut rate and longer tool life. |

| Available size: | 4.5", 5" |

| Popular grits: | 60# 120# 200# 400# |

| Available grits: | 60# 120# 200# 400# 600# 1000# 2000# 3000# |

| Flaps: | Flexible flaps in pound sign pattern |

| Base: | Fiberglass backing with aluminum M14 or 5/8-11 thread |

| Usage: | Wet and dry |

| Applied machine: | Hand-held grinders |

| Applications: | For concrete floor edge work: shaping, leveling and grinding the edge and corner of concrete floors where walk-behind floor grinders can not reach. |

Diamond Flap Grinder Disc

Compared with the cup wheel, our diamond disc provides smooth and uniform grinding, provides protection for the operator, and significantly reduces hand and arm vibration! The service life has been increased by more than 100 times, making it more durable and efficient.

Diamond Flap Grinder Disc Specification:

The Flap Grinder Disc is designed for fast material removal applications on all hard, brittle materials without the need for high pressure. This flap disc comes with a combination of diamond and silicon carbide flaps on a reinforced plastic backer pad. Each flap makes line contact so that the disc will maintain fast, aggressive cutting without having to apply pressure. Although it is designed for high-speed angle grinders, for the best results, We recommends using at 8,000 rpm if the grinder has a variable-speed control switch. While the Flap Disc is great for dry use, it can be used wet to keep the dust down, for higher performance and a longer life.

In general, you’re better off using a flap disc when abrading metal and applying a smoother finish. Although they’ve long been used with high-speed angle grinders, advances in both design and materials have brought flap discs to the point where they can carry out grinding, blending, and finishing jobs much more quickly and with less noise than grinding wheels- layered flaps constantly expose new grain and act as a cushion, resulting in less noise and vibration.

Other advantages include:

Grinding wheels can play an important role in your project, particularly during material removal, but when you’re working with metal and need a tool that can achieve results during each stage of the project, flap discs may be your best and most efficient option.

The Company Profile of Xiamen ZL Diamond Technology Co., Ltd.

✔Production is run strictly sticking to ISO 9001:2015 quality system, which makes us leading place in efficiency and quality within the industry.

✔Our entire ISO9001 quality management system production process includes raw material testing, production site inspection, finished product inspection, product testing, packaging, etc.

✔Our R&D and workers are all with rich experience for producing products with high accuracy and the material is with special made by our engineers.

✔Contact us, you will get more than what you see.

-FAQ:

Q1. Are you trading company or factory?Do you have your own brand?

A1: Yes,we are.We are factory with trading business. We setted up more than 20 years and export more than 15 years.It is very convenient to visit our factory.

Our brand name is Z-LION & Z-LEAP, we can provide OEM and ODM services to our customers as well.

Q2. How do Z-Lion Diamond Tools Group control the product quality?

A2: Production is run strictly sticking to ISO 9001:2008 quality system.Meanwhile, we have a well trained professional QC team, each product have a very strict quality control system.

Q3: Can you make sample for testing?

A3: Yes, we can make sample according to customer requirement, 产品 can be provided for free.

Q4. Do you accept trial order?

A4: Yes, small order is welcomed.

Q5. What is packing term?

A5: We use export standard cartons, cartons size is according to the product specification.

Q6. What is delivery time?

A6: 5-7 working days after receive payment.

Q7. How about payment?

A7: T/T, L/C,Western Union,PayPal, Others.

-All diamond tools can be ordered and fabricated!

-Henry Wang | Quote Manager

-WhatsApp:+86-18030177538

-Email: ceo@zdiamondtools.com

-Web www.zdiamondtools.com

Company Profile

You can contact us any way that is convenient for you. We are available 24/7 via fax, email or telephone.